Design Services and Build-to-Spec

Design Services and Build-to-Spec Equipment

Build-to-Spec Equipment

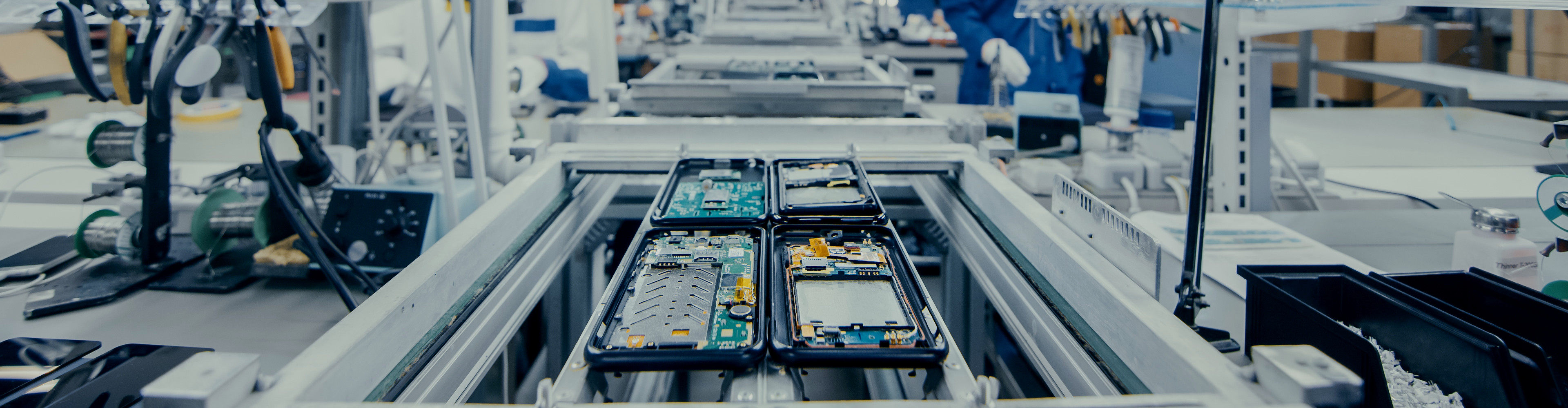

The Build-To-Spec subcontracting mode means that from a client’s specifications, we not only carry out the design but also the mass production of your systems under our responsibility.

Oxytronic has, at its main site in Aubagne (France), high-level know-how and high-performance means to produce prototypes and launch mass production of your systems and equipment:

- CMS pick & place machine,

- Takaya test machine,

- thermal test chamber,

- machining center,

- sand blast machine,

- paint cabin,

- laser engraving center,

- NVIS light and color control and harmonization equipment.

Oxytronic therefore offers its customers a full range of services from concept design to mass production of embedded electronic equipment in Build-to-Spec and Build-to-Print.